Decorative Solutions

Interior Decor Parts

Product- and system requirements

Interior decor parts

- High quality palstics surfaces for A, B, C trim pillars and lower instrument panel

- Interior trimparts with functional integration (airbag cover)

- Optimized gap design

Innovations

- Fully automated assembly of clips, mats etc.

- In moulded fabric to secure airbag function

- Compensatory tolerances

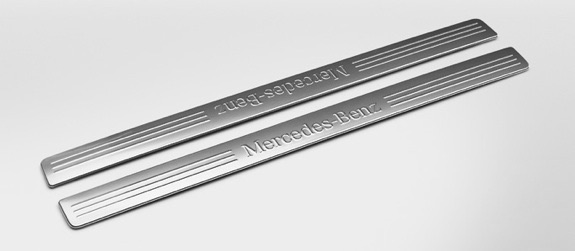

Sill Plates

Sill Plate

Product- and system requirements

- Back moulded sill plates with steel / aluminium foil

- High gloss surfaces (premium standard)

- Real metal optic (truth in material)

- Functional integration

- High resistance against environmental influences

- Weight reduction

Innovations

- Process integrated metal foil bending (tool technology)

- Reduced complexity of supply chain

- CAD simulation of back moulded parts

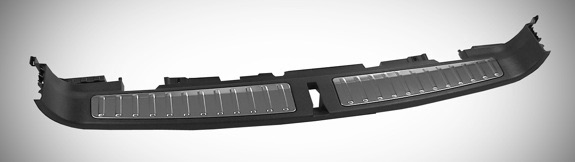

Scuff Plate

Scuff Plate

Product- and system requirements

- Functional integration

- In mold plastic components with metal foils

- High stressed surfaces

Innovations

- Process integrated metal foil preforming (multilevel production processes)

- Lay out design of components by coupled simulations

- Simplified assembling

Garnish

Garnish

Product- and system requirements

- Class A surface without painting

- Noise damping

- Functional integration (loudspeaker, design bezels)

- Invisible parting line

Innovations

- Innovative tooling concepts

- Forced demolding

- Use of recyclate

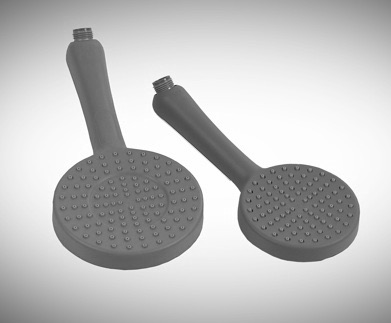

Spray Element for Bath and Kitchen

Spray Element

Spray Element | Source: Hansgrohe

Product- and system requirements

- High gloss product surface (chromated)

- Invisible parting line

- Scroll-mode for water guides

- Prevention of calc accumulation

- Fully covered switch surfaces

- Minimized water use

Innovations

- 2K-LSR-spray

- Modular water guide concept

- Pressure optimized valves

- Integrated valve gates

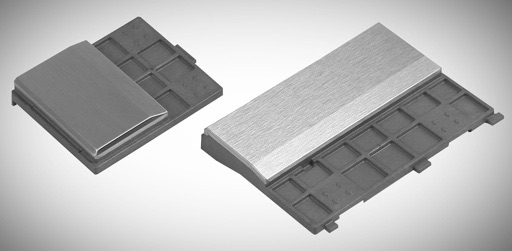

Actuator Button

Actuator Button

Product- and system requirements

- High quality surface

- Metal feeling

Innovations

- Aluminium foil backmolded

- Small radii on edges

- Anti finger-print top coating

Handles

Handles

Product and system requirements

- Thick walled moulded part made by super transparent PMMA

- Injection moulding process to produce a part with strongly varying wall thickness (2 – 10 mm)

Innovations

- Insert with PVD coating

- Ultrasonic welding within direct viewing range

Fuel Filler Inlet

Fuel Filler Inlet

Product and system requirements

- Sealing

- Chemical resistance

- Compensation of BiW tolerances

Innovations

- 2K injection molding

- Paintable material for fuel filler cap